Welding is the process of combining materials by melting them through sufficiently high heat and subsequently letting them cool down so that they strongly join together.

However, the term itself isn’t as much straightforward as we think.

There are many complex and diversified types of welding process exist so as to appropriately carry out the combining process according to the primary objective.

Assuming this fact, we are going to share with you about 14 different types of welding process and what they are used for.

So let’s begin:

Different Types Of Welding Process

1. Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding is the simple process of manually joining materials through decomposing a wire of electrode that’s been covered with flux and is laid down between the metal and electrode with the form of an arc.

The process is fueled by an electric current and as soon as the melting process is performed, the disintegrated electrode generates some vapor which is generally known as the shielding gas and thus produces a slag layer across the welded area. This layer protects the metal from all sorts of atmospheric contamination.

Let’s explore some of the benefits and flaws of this particular welding process:

Advantages: The main advantage of this welding process is its simplicity and inexpensiveness. Besides, it is one of the most popular and widely used welding processes because of its versatility and simplicity.

Disadvantages: Two of the common flaws associated with this process is porosity and weld spatter. Two other usual drawbacks which are the risk of burn and skin damage can occur from any other welding process if sufficient precautions are not carried out properly.

2. Plasma Arc Welding:

Plasma Arc Welding is performed through forming an electric arc right in between the workpiece and the electrode. The electrode is generally positioned inside the torch and the plasma goes through a copper nozzle which consequently forms the arc.

If you read through the types of welding processes we have discussed here, you’ll see this process is quite similar to that of Gas Tungsten Arc Welding whereas the only difference lies on the ability of the first one to separate the shielding gas from the plasma arc.

Let’s learn about its benefits and drawbacks:

Advantages: The torch which is designed to perform Plasma Arc Welding enables a welder to be efficient enough to get the controlling of the arc and therefore to observe the overall welding process. Besides, the plasma jet and increased heat concentration ensure faster travel speed.

Disadvantages: The types of equipment used in Plasma Arc Welding are relatively expensive than that of other processes which result in higher startup cost. Besides, some specialized training is required for the welders to appropriately carry out this task.

3. Flux Cored Arc Welding (FCAW):

Flux Cored Arc Welding is performed through a continuously fed electrode wire which has flux in it and continuously runs on a constant welding power supply system. The arc area is protected by the continuous supply of shielding gas that protects the weld pool from all sorts of atmospheric contamination. Besides, the shielding gas is usually supplied from an external link & the flux also works as a protective supplement for contamination.

Flux cored arc welding is very popular among the welding industry because of its portability and speed. Flux cored welding is quite similar to that of MIG welding although both of them have several technical differences.

Advantages: Some attractive benefits of using this welding process are low startup cost and a higher deposition rate. Besides, most steel applications don’t require any shielding gas to be applied while performing this process. On top of that, the chances of porosity are super less in comparison to other welding strategies and the electrodes are very inexpensive as they are flux cored.

Disadvantages: One of the common problems of this strategy is the sensitivity of the electrode as it’s been made from mild steel or alloy. This attribute is also known as voltage tolerance which can be bypassed by supplying shielding gas to the weld pool and by maintaining a constant electrode feeding speed.

4. Submerged Arc Welding:

As the name suggests, Submerged Arc Welding also uses a continuously fed electrode wire to molten the arc before which the weld pool is submerged under a flux layer consisting silica, lime, manganese oxide, and other supplements. This flux protects the welding area from all sources of atmospheric contamination as well as prevents weld spattering and decrease high ultraviolet radiation.

However, no shielding gas is required to carry out this process. In addition, there is no possible means for heat loss as the whole arc is covered with a layer of flux and the slag layer can be removed subsequently.

Advantages: Some advantages of this process include high deposition rate and the ability to prevent weld spattering to the weld metal. Besides, it has faster travel speed and can protect the air from high radiation.

Disadvantages: The key limitation of this process is only a handful number of materials can be welded through using this welding process. And these are stainless steel, nickel alloy, and steel.

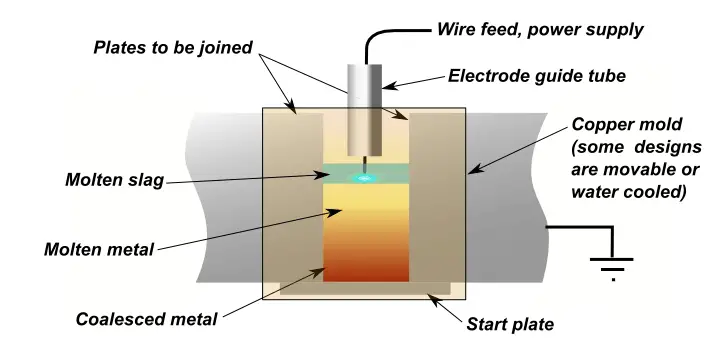

5. Electroslag Welding:

Electroslag Welding is a bit complex and different process from that of other welding processes. The main parts that play the key role are the electrode and flux.

Basically, the flux does the main work. It melts the filler metal and the workpiece by transforming electrical energy into heat energy and subsequently, this heat establishes the joint.

At first, the arc is produced between the electrode and the base metal after which the flux is added. Now, this formation produces a high temperature that naturally heats the flux and produces a slag layer.

Consequently, the slag reaches a temperature of 3500F which is sufficient to melt the metals and made a strong joint between the electrode wire and the workpiece.

Advantages: The main advantage of this welding process is the low cooling rate that prevents it from cold cracking. Besides, the process is quite faster and there are very low chances of porosity because of the sophisticated system.

Disadvantages: A key drawback of this welding process is the limitation in carrying out the task on vertical positions only. Besides, the excessively high temperature may sometime require a heat control system.

6. Gas Metal Arc Welding (GMAW/MIG):

Gas Metal Arc Welding, also known as Metal Inert Arc Welding is a simple welding process that produces an arc between the electrode and the weld metal whereas, the electrode is fed by a nozzle within which there’s another separate nozzle for the shielding gas to pass. This shielding gas protects the weld metal from all sorts of atmospheric contamination.

Apart from that, a constant welding power supply is required to effectively perform the task. GMAW welding can be performed by using one of these four methods: short-circuiting, pulse spray, globular or by normal spray.

Advantages: Some advantages of the GMAW process includes higher travel speed, low hydrogen welding which can prevent unwanted hydrogen cracking. Besides, the ability to easily switch from semi-automatic to fully automatic for increased output.

Disadvantages: The gun size is relatively larger which can be an obstacle for reaching smaller areas. Besides, the startup cost is a bit high because of the complex equipment needed to duly perform this process.

7. Gas Tungsten Arc Gas Welding (GTAW/TIG):

Gas Tungsten Arc Welding, aka Tungsten Inert Gas Welding, is a unique welding process where the electrode is generally non-consumable and is used to perform the welding duty & the formation of an arc.

As the name suggests, the electrode is basically made of tungsten. The weld area is duly protected by a shielding gas that comprises Helium and Argon.

Filler metals can be used in the welding process if it’s thick, otherwise, there’s no need for using any filler metal for thinner materials and welding joints.

Advantages: Some advantages of this process include zero weld-spattering and concentrated arc formation which allows a welder to reach narrower weld areas to provide intense heat. Apart from that, as no fluxes have been used on this process, there is no production of slag.

Disadvantages: Two of the key limitations of this process are the lower travel speed and lower deposition rate of the filler metal.

8. Laser Beam Welding (LBW):

Laser Beam Welding is a simple welding process that uses a laser beam to supply concentrated heat to the desired welding area which consequently melts the welding metal and forms a joint between the two edges.

There are basically four types of equipment needed to carry out this task. They are the laser, a continuous power source, CAM & CAD integration for the design and precise operation by the computer. Shielding gas might be used while performing this welding task.

Besides, this process is mostly used in highly automated industries such as electronic equipment manufacturing and automotive.

Advantages: Some lucrative advantages of this process include narrow heat affected zones, strong and precise welding, ability to weld a broad range of metals, lower scrap generation and the fact that the light can be placed while making a distance from the welding metal.

Disadvantages: The key drawback of this welding process is the higher purchase cost of all equipment, including the filler material. Besides, maintenance costs are also high and specialized workforce is needed to carry out the whole task.

9. Electron-Beam Welding:

Electron-Beam Welding is performed by supplying high-velocity electron beams to the welding area which consequently melts the metals and strongly joints the edges.

Besides, no filler materials are used to carry out the process. To prevent electron beams dissipation, the process is performed under vacuum conditions.

Electrons are generally produced by electron guns after which their speed is highly accelerated through electrical fields.

Subsequently, they are precisely focused and applied to the welding materials by using magnetic fields.

Advantages: Advantages of this process include smaller heat affected zones, strong and precise welding, and the ability to join dissimilar materials which can be a crucial advantage for any welder. Besides, this process doesn’t require any filler material which leads to low cost.

Disadvantages: Some drawbacks of this process are the complexity of the equipment and the initial startup cost. Besides, safety measures should be taken against harmful radiation.

10. Laser-Hybrid Welding:

Laser Hybrid Welding process is the combination of Arc welding and Laser Beam Welding. This process is performed by initially heating the surface of the workpiece with the help of a laser.

This way, the metal reaches at its vaporization point and makes a narrow and deep penetration to that area. Afterward, the arc is formed precisely onto the edges which will lead to a strong fusing of the parts.

Advantages: Some advantages of using Laser Hybrid Welding include higher welding speed and the ability to join difficult welding materials because of its strong energy generation.

Disadvantages: The only drawback may include the initial setup cost which is comparatively less than normal laser beam welding.

11. Resistance Welding:

Resistance welding is performed by supplying a continuous flow of electric current to the weld metal that provides heat to that area and consequently melts the metals to be joined together.

Besides, a continuous force or pressure is simultaneously supplied to that area which helps to solidify and strongly joints the edges together.

There are four types of resistance welding methods which are frequently used. They are seam welding, spot welding, resistance butt welding, and flash welding.

Advantages: Some benefits of using Resistance Welding are higher welding rates, cost efficiency and the ability to automate the process in an effortless manner. Besides, it generates very low fumes and distortions.

Disadvantages: Two of the common flaws associated with this process are higher startup cost and discontinuous welding that usually result in lower strength.

Additional Read: Best Battery Spot Welders

12. Carbon Arc Welding:

Now, Carbon Arc Welding is performed by a non-consumable carbon electrode whereas the heat is produced from the electric arc which melts the filler rod to form a strong joint.

Application of shielding gas is optional for protecting the metal from atmospheric contamination.

However, this type of welding has been in use since the invention of the welding method itself for which it can be considered as the oldest welding method on the list.

Advantages: Some advantages of Carbon Arc Welding are lower equipment cost, low workpiece distortion and ability to easily automate the process on demand, without hiring any special workforce.

Disadvantages: Sometimes, the weld metal gets contaminated with the carbon inside the electrode.

13. Gas Welding (GW):

Gas Welding is generally performed by supplying continuous flame from the welding torch.

The torch simultaneously supplies oxygen from another cylinder along with the fuel gas in a required proportion.

This flame causes the melting of the parts and forms a strong joint after solidification. Use of filler rod is conditional and fluxes might be used to protect the weld pool from contamination.

There are mainly three types of gas welding methods that are frequently used. They are oxyhydrogen welding, pressure gas welding and, oxyacetylene welding.

Advantages: This process is quite beneficial for its versatility and portability. In addition, it doesn’t require any electricity to carry out the task and the costs of equipment are relatively lower in comparison to other welding processes.

Disadvantages: Special workforce is required to carry out this welding process.

14. Thermit Welding (TW):

Thermit Welding is a simple welding process that uses an exothermic chemical reaction to produce heat.

Basically, this Thermit is comprised of a combination of aluminum powder and metal oxide that produces heat after reaction and, therefore, melts the metal which creates a strong joint after solidification.

This process is often used over steel parts.

Advantages: Two key advantages of using this process are the ability to weld larger and thicker parts of metal. Alongside, no electricity is required to carry out the task

Disadvantages: Range of welding parts is limited to Steel, Nickel, and chromium. Besides, the welding speed is relatively slower than other welding processes.

Final Words

Thanks for reading the whole article. We believe you’ve got a comprehensive idea about all the different types of welding process and what they are used for.

We are always in a process of enriching our site with exclusive welding related guides and articles for you. Stay tuned with us. We appreciate your presence.

It’s interesting that plasma arc welding has a faster travel speed as well as efficiency. I’m wanting to get a custom metal shape welded that has an outline light of the mountains etched in. I’ll be sure to find a welder that can do this specific job for me.