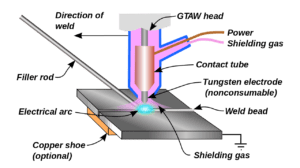

TIG welding is basically unique for using a non-consumable tungsten electrode to supply adequate current for performing the welding task. The process is alternatively known as Gas tungsten arc welding (GTAW). However, using filler metal is optional which depends upon whether the welding is autogenous or not. Besides, shielding gas is also used in TIG welding to protect the whole process from atmospheric contamination.

Now, TIG welding is mostly used because of its simplicity and ease of application. Although the process is a bit slower than that of other processes like MIG welding and Shielded metal arc welding, it allows the welder to have more control and flexibility over the whole welding process which results in a durable and sustainable fusing of that area.

Let’s learn in details about what is TIG welding and what are the notable areas over which TIG welding is mostly used.

Additional Read – Difference Between MIG and TIG Welding

What is TIG Welding Used For?

TIG welding offers a vast range of materials that can be easily welded. However, materials that are usually thin in nature mostly use TIG welding to perform the combining task. For this reason, the aerospace and bicycle industry primarily uses TIG welding to manufacture their products. On the other hand, magnesium and aluminum made materials with most sorts of maintenance and repair works such as piping are also performed by TIG welding.

In addition, its ability to prevent metal corrosion for a long period makes it a perfect choice for this type of work. Now let’s head over to all the detailed steps by which you can appropriately and professionally perform TIG welding with due regard to some cautionary factors.

Detailed Steps And Cautionary Steps Of TIG Welding

Choosing And Preparing The Electrode

If you’re planning to weld aluminum materials, you should definitely choose a tungsten electrode. Besides, there are also other types of tungsten electrodes including thoriated type which is basically radioactive. Now, preparing the electrode means to ensure the tip is round-shaped otherwise you have to grind it before using.

Our recommendation will be to use a ball-shaped tip and a pointed tip for welding over AC and DC power respectively. You got to make sure that your tungsten electrode doesn’t touch your workpiece otherwise it may create an unusual sound which denotes to the contamination of the electrode.

Lastly, you have to practice the feeding work as frequently as possible while altering the temperature and type of electrode in order to become an efficient TIG welder.

Additional Read: Procedure to clean and prepare metal before TIG welding

Preparing The Shielding Gas

TIG welding basically uses argon and carbon dioxide for welding materials made of aluminum and steel respectively. However, in the case of steel welding, you can use both carbon dioxide and argon interchangeably. This gas duly helps to prevent the welding work from having any sort of metal contamination. One thing to remember, you can’t use the same gas for MIG and TIG welding.

Preparation Of The Welding Metal And Space

Now the weld metal needs to be prepared if you want a clear finishing after the weld. You can simply use a brush made of wire for scrubbing the metal’s surface. Alternatively, aluminum or stainless steel brush can also be a perfect choice for performing this task (Use the brush made of similar material like the weld metal for preventing contamination).

On the other hand, clamping essentially helps to retain the position of your weld metal throughout the weld. You can also spray anti-spatter which will rescue the welding from leaking off while retaining the surface flat.

Safety Measures

One of the crucial things to consider while welding through any process is to ensure adequate safety preparation before performing the welding task. TIG welding isn’t out of this condition. There need to be sufficient safety measures in order to prevent any potential accidents like burning your skin or having eye damage.

In this case, you can use welding gloves, dark helmets, and toe shoes while wearing a jacket or shirt which is long-sleeved. Besides, cleaning your helmet before welding will allow you to observe the process way more transparently and bright light can be used to do the task.

Starting To Weld

One thing to consider while TIG welding is to make sure the electrode has been positioned a bit distant from the weld metal. In other words, it doesn’t touch the weld metal since it may result in the molten metal to jump across the electrode.

Now, put some force on the Pedal and quickly heat the weld metal. This will quickly produce a weld pool on that area and force the metal to get molten which is ideal for initiating the weld.

You have to keep in mind that you shouldn’t direct too much heat to the weld metal otherwise it may become bent or shrink away after being cold. So make sure to decrease the pedal jamming right away after the weld pool is formed. Besides, alternating sides while welding will prevent minor damages from shrinking off or too hot metal and ensure a smooth and even weld of that area.

Once the weld pool is formed, just feed the rod inside the weld pool while positioning the electrode towards it. This process is best suited for welding aluminum made materials. Besides, if the weld metal is yet to be melted, just put some more jamming on the weld paddle while conversely if it seems to get burnt, just stop the jamming.

Different Types Of TIG Welding

There are basically three types of positions by which TIG welding is performed. They are fillet, butt and lap welding. These are very common and you may be already aware of their positions. But for further reference, fillet welding is the most common category of welding where the right angles of both weld metals are joined together. Butt welding is a common 180-degree joint which can be both single-sided and double-sided. Lastly, lap welding joins two metals while the first one is standing unequivocally over the other.

Now, apart from these three types, there are also another two types of welding which depend upon the strength and beauty factors of the metals being welded. They are cosmetic and strength welding.

Strength welding is performed over materials that are built to last. This means those products that usually carry a lot of weight such as cylinders and propane tanks. In this case, the rod is continuously fed into the weld pool throughout the welding.

On the other hand, cosmetic welding is performed over materials that are highly visible such as bicycles or cars. Just draw a rough line in the weld pool while positioning the rod. This will retain the aesthetic attribute of the weld metal.

Some Other Things To Consider

You can also use the soft start and soft stop techniques for preventing any potential contamination to take place. The soft-start denotes to heating up the metal while slowly increasing the amperage whereas the soft stop is to slowly bring down the heat by decreasing the amperage settings.

Final Words

Thanks for reading the whole post. Our objective was to provide you with all the detailed and crucial information by which you can appropriately perform TIG welding like the way a professional TIG welder does in practice. But becoming one will depend upon the frequency and interval of your practice which will produce the intuitive wisdom inside you for professionally carrying out any welding task. Stay tuned with us. We appreciate your support.

Suggested Articles –