Today, I’m going to talk about two not-so-cheap MIG welders, namely Hobart Ironman 230 and Miller 252. These machines are equipped with everything that you would want in a decent and powerful MIG welder.

Both manufacturers have a large crowd of happy customers whose loyalty contributes to these brands’ solid reputation. Facing the competition, both companies focus on quality, durability, and usability of products, often putting customers in a difficult situation as they want to purchase something.

In my opinion, the welders mentioned above make a perfect example of what I’ve already suggested. A quick look at their technical specs might give you the idea that they are interchangeable when they are not. So, I’ve decided to review and compare these units, so you can tell where one can be better than the other.

Hobart Ironman 230 Vs Miller 252: A Quick Comparison Chart

I know a few numbers may not help everyone, but I want to present you with a bunch of information, in case you already know the basics of MIG welding and the appliances used for the process.

Table could not be displayed.Hobart Ironman 230 Vs Miller 252: In-Depth Comparison

I’ve tried to reveal facts about these welders in terms of their power, performance, build quality, and other technical considerations. I hope you’ll find them helpful and reach a well-informed decision in the end.

Hobart Ironman 230 MIG Welder Review

If you ever have a quick conversation with a salesperson from a welder brand, you might have heard catchphrases like ‘flawless weld,’ ‘less spatter,’ ‘minimal post-weld clean-up,’ ‘tool-less setup’ — you name it. Hobart 500536 comes with these selling points as well.

Build, Ease Of Use, And Safety

The hefty package includes a 224-pound welder, a 15-foot MIG gun, a liner, a flow meter/regulator, a 5-foot gas hose with required fittings, a 10-foot work cable and clamp, a safe power cord and a plug, a .030-/.035-inch drive roll with two grooves, and extra contact tips (.030-inch).

The unit has a durable cabinet. Its front panel sports a sloped design to allow the operator to see the different switches, knobs, and control hardware, and access them easily. The spool hub comes with an assembly that accommodates spools with variable weights, including 2 lbs., 10 lbs., 33 lbs., and 45 lbs.

You don’t need special tools to operate the machine as it features a knob to control the brake tension. You won’t have difficulties aligning the wire because alignment occurs automatically.

The drive roll is designed to be a reversible, one-piece component with two grooves to allow two different wire sizes. It eliminates the need for spare parts, frequent stocking, or change over time.

Built with aluminum, the wire drive relies on a dual-geared mechanism to deliver wire feed speeds ranging from 0 ipm to 700 ipm. You can use the hinged door to change the drive roll or spool almost effortlessly.

Built with aluminum, the wire drive relies on a dual-geared mechanism to deliver wire feed speeds ranging from 0 ipm to 700 ipm. You can use the hinged door to change the drive roll or spool almost effortlessly.

A look at both sides of the unit brings the dual cable hangers to notice, and you can store cables in there when you don’t need to use them.

You can control the wire feed speed with infinite speed settings that help shape the weld bead and increase penetration with precision. Add Hobart’s DP 3545-20 spool gun to your list if you are tasked with aluminum welding.

The machine uses a cooling system comprising a fan that runs only if the application demands. This on-demand component helps reduce the unit’s power consumption and prevent unwanted contaminants from being drawn directly into it.

Power And Performance

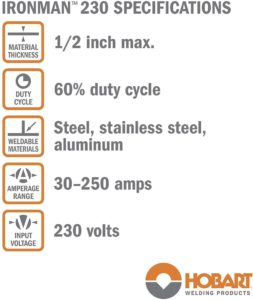

Who doesn’t want to adjust the voltage just as much as a smooth arc requires? Use the 12-tap settings to control the voltage, so you can have a smooth arc that is not hard to control. This welder operates on a standard 230V and delivers at least 30A and up to 250A (output) with a 60% duty cycle at 175 amps.

Material Thickness

Hobart Ironman 230 may not be the finest example of a versatile MIG welder, but it allows you to weld mild steel and pursue flux-cored welding with ease. Starting from 24-gauge mild steel, you can weld up to 1/2-inch metal.

Flux-cored welding also becomes a breeze despite some compromise on thickness. However, you have to rely on single-pass applications to work with thick plates and base metal.

Applications

Repair, maintenance, fabrication, and auto body restoration are the recommended fields of application. This versatile unit lets you extend your enthusiasm to a few more areas such as metal art, farm, ranch, and light construction work.

Pros

- A complete package containing high-quality components and a durable welder

- Excellent arc stability and convenient voltage adjustments for inspiring precision welding

- Well-designed drive-roll and cooling system for enhancing operational efficiency

- Availability of quite a few compatible accessories (sold separately)

- Reliable warranty support

Cons: Hobart Ironman 230 Problems

- Not a lightweight welding machine

- Poor support for stainless steel

A Few Tips

Though you may find the claim’ less spatter’ appealing, improper use of argon or carbon dioxide may lead to excessive spatter causing you sheer frustration. You should consult your operator manual for the right settings and amount of shielding gases recommended for different applications.

For the machine to deliver maximum output where you cannot help using a portable power source, make sure you keep an 11000-watt generator. I guess you have all the information you need except the price. Here it is.

Miller 252 MIG Welder Review

Looking at the price, I wanted to conclude that Hobart Ironman 230 would be no match for Millermatic 252. But then my curious mind went a little further into the details and discovered something interesting, which led me to this section.

As I can bet you won’t settle for anything that is just above the average class of welders, I am sure you’ll find the rest of this comparative discussion considerable.

Build, Ease Of Use, And Safety

Some of the welders I’ve seen are designed in a way that you might easily bump into the unit while working. Even you might risk bending the MIG gun or the gun liner. With Miller 252, you won’t have these issues. Let’s explore other areas.

You know that you cannot do much of a weld without correct parameters. With Millermatic 252, getting those settings right becomes easy with an infinite voltage adjustment and a precision mechanism for the ‘wire feed speed (WFS).’

You can also see the numbers on an integrated digital meter that automatically calibrates as expected by the operator. This gadget comes with several timers for burn-back, post-flow/pre-flow, delay (stitch), and spot welding.

Separate timers are available for both spool and MIG guns. Even better, the machine is designed to preserve the settings from a previous session. This ‘recall’ function significantly reduces the time for setup.

An angled drive system is in use for this unit. It comes built with heavy-duty industrial aluminum. The dual-gear mechanism accepts large wire spools and improves the speed of the wire feed.

You won’t be looking for extra tools to change the drive rolls. A storage compartment is located close to the drive motor to accommodate extra rolls.

The line voltage compensates itself to ensure that power remains constant in case of any variation of power input up to ±10 percent. An active component comes integrated to stabilize the arc so that you can expect a smooth start and put a little clean-up effort after a welding operation.

The ‘Auto Gun Detect’ mechanism eliminates the hassles of identifying the right gun for your preferred welding process. You can connect the unit and the guns without using any additional module or tool.

With the gun connected, you can pull the trigger on your spool or MIG gun and start ‘push’ or ‘pull’ just as your chosen application requires. You can choose to connect any gun from Spoolmate™ 200, XR push/pull, and Spoolmatic spool gun.

The EZ-Change rack allows you to use gas cylinders without lifting them. The low rack makes it easy for the cylinders to roll on or off as needed. The split handles use rubber grips, so you can move the machine while keeping the MIG gun and front panel protected. These dual-front handles also let you store the gun and the lead separately.

The EZ-Access compartment provides enough room for the parameter chart and consumables. It flips down easily to allow quick access to those items. I think this compartment is proof that Miller emphasizes the operator’s convenience.

Power And Performance

This welder operates off 208/220/230/240 V. If you want to use a wide variety of wire types and sizes, you need an extended range of amperage, which is one of the top benefits this unit offers.

You’ll get 30 amps to 300 amps of current. Rated output is 200 amps at 24 volts of DC at a 60% duty cycle. At a higher VDC (26.5) and output (250 A), you’ll get a 40% duty cycle. Open-Circuit voltage stays at a maximum of 38 V.

Material Thickness

It is good to have a welder that handles all three common metals such as aluminum, mild and stainless steel. I wouldn’t doubt this machine’s excellence except for stainless steel, which may not be the best base metal to weld with Miller 252.

If you have your way around this unit, you can handle stainless steel too. You won’t have much of a problem with aluminum and mild steel. So, I’ll tell you the recommended thicknesses for these two metals.

- Mild Steel 0.9 mm (22 ga.) to 13 mm (1/2 in.)

- Aluminum 19 mm (14 ga.) to 9.5 mm (3/8 in.)

Applications

Do you remember which applications I mentioned as I talked about the Hobart Ironman model? This Miller welder is designed for those purposes, except ‘light industrial work,’ where this one works better than the Hobart machine.

Pros

- Enhanced arc stability with excellent support for reusable parameter settings

- Powerful (output current and duty cycle) enough to handle common metals and a wide range of thicknesses

- Ideal for beginners, DIY, and experienced professionals

- All essential features for effective and safe welding operations

- Excellent warranty support

Cons

- Heavier than most units in the same class

- Not one of the budget-friendly models for DIY uses

Final Verdict

After everything you’ve learned so far, I guess you cannot wait for a concluding remark from me. Besides wrapping up the entire discussion, I won’t take this any further, my friend.

Hobart Ironman 230 is the more affordable and lighter of the two welders. Speaking of its performance, I would choose this machine over Miller’s for mild steel. Yes, you’ve read it correctly. Ironman 230 outperforms Miller 252 when mild steel is in question.

Then why are you even thinking of a welder that weighs as much as 93 kilograms and costs almost double? My answer is versatility. Millermatic 252 has a solid appeal to more experienced professionals who want to look beyond mild steel and DIY projects.

Enough for today! Don’t you think? By the way, don’t hesitate to ask if you ever have a question about these two welders or other models. I’ll get back with a reply. Happy buying!