When welding, the goal is to join two pieces of metal together. In order to do this, you must first melt the metals so that they can be fused together. However, you don’t want to overheat the metals or they will lose their strength and could potentially break. So, how do you find the right balance?

Well, you need to have adequate knowledge about the cooling rate, heating rate, and solidification rate and optimize them properly to produce a flawless weld. Now, I’ll discuss each of these rates and how they impact welding so that you get better ideas about them.

As a welder, it’s important to understand the cooling, heating, and solidification rates of the material you’re working with. This will help you control the welding process and produce high-quality welds.

So, let’s see everything regarding these three rates and how to optimize them for a successful weld.

Cooling Rate In Welding

The cooling rate in welding is an important characteristic that affects the mechanical properties of the welded joint. It is an important thing to consider while welding. A slow cooling rate can result in the formation of brittle crystals, while a fast cooling rate can prevent the metal from hardening properly.

Also, the cooling rate of a metal object isn’t identical in all places. It varies and you should know the cooling rate of the spot you are going to weld.

But, do you know why cooling rates vary?

Well, when you perform the fusion arc welding, an arc is used to apply heat to the melting surface. When you apply heat, solidification takes place. At that moment, both the welded region and its nearby regions show different cooling rates. That’s why the Heat Affected Zone and the weld region get different cooling rates.

Therefore, it is crucial to measure the cooling rate of the metal surface so that you can properly control it. If you don’t control the cooling rate rightly, it can hamper the soundness of your welder metal. So, you should know how to calculate the cooling rate. Don’t worry, Now, I will give a simple formula for measuring the cooling rate easily.

How to calculate the cooling rate in welding?

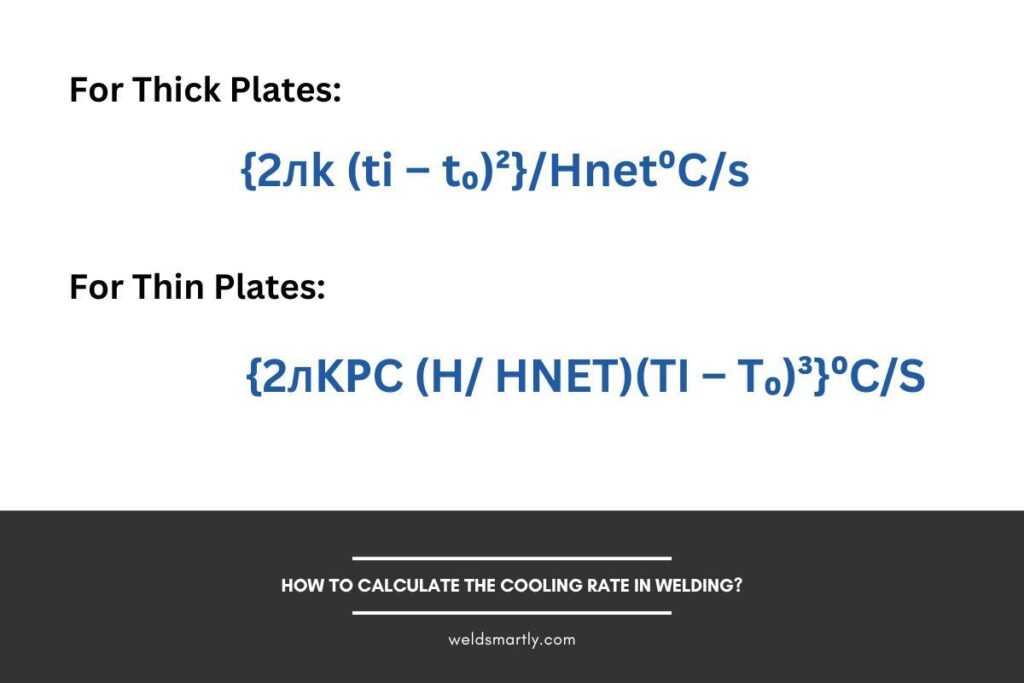

The cooling rate of a weldment can be calculated using two different equations. One for thin plates and another if they are thick, depending on the welding conditions.

For thick plates, the equation to calculate the cooling rate is-

{2ᴫk (ti – t₀)²}/Hnet⁰C/s

Here, k stands for thermal conductivity, Hnet is the given heat, ti is the desired cooling rate temperature or temperature of interest, s is time measured in seconds, and t₀ defines the initial plate temperature.

For thin plates, you can calculate the cooling rate by the following formula-

{2ᴫkρC (h/ Hnet)(Ti – T₀)³}⁰C/s

Where h= the plate’s thickness(mm), ρ = density of the plate(g/cm³), and other symbols(k, Hnet, s, ti, t₀) have been mentioned before.

What factors affect the cooling rate?

When welding, it is important to cool the metal gradually to prevent any potential damage. Let’s have a look at what factors affect the cooling rate.

1. Preheat and interpass temperature

Preheating the workpiece can help to control the cooling rate by reducing the amount of heat that is lost to the environment during welding. Interpass temperature is also important, as it can help to prevent cracking and improve the mechanical properties of the weld.

2. Speed of welding

Welding speed has a direct effect on cooling rate, as slower speeds allow more time for heat to be conducted away from the weld. That’s why, beginners may face this high cooling rate issue frequently as they work much slower than any professional.

3. The thickness of the metal

Workpiece thickness also affects the cooling rate, as thicker materials take longer to cool down. In general, thicker metals and metals with a higher melting point will have a slower cooling rate than thinner metals or metals with a lower melting point

4. Cooling blanket

One of the most important factors that affect the cooling rate in welding is the use of cooling blankets. Cooling blankets are made of a variety of materials, such as water-resistant PVC, fire-retardant fiberglass, and aluminized mylar. They are used to protect the weld zone from heat, sparks, and UV radiation.

The blankets also help to keep the weld pool cool, which helps to reduce the risk of weld defects.

5. Type of Welding Process

Another factor that affects the cooling rate in welding is the type of welding process that is used. For example, MIG welding generally cools down faster than TIG welding. This is because MIG welding uses a constant stream of argon gas to shield the weld pool, which helps to cool it down quickly. TIG welding, on the other hand, uses an arc to create heat, which means that it takes longer for the weld pool to cool down.

6. Ambient Conditions

Ambient conditions also affect the cooling rate. If the temperature is too cold, the cooling rate may increase significantly compared to hot summer days.

So, by taking all of these factors into account, welders can help ensure that their welds are strong and durable.

Heating Rate In Welding

The heating rate in welding is the speed at which the metal heats up during the welding process. It is closely related to both heat conduction and energy input and can have a significant impact on how well the weld is made.

In other words, the rate at which a welded item is heated is determined by the heat source’s temperature and the workpiece’s heat transfer efficiency. The heating rate in welding depends on travel speed, amperage plus voltage. The recommended heating rate for carbon steel & alloy steel is around 30-70 KJ/inch.

Remember, the heating rate should be enough to melt the weld zone metal base efficiently.

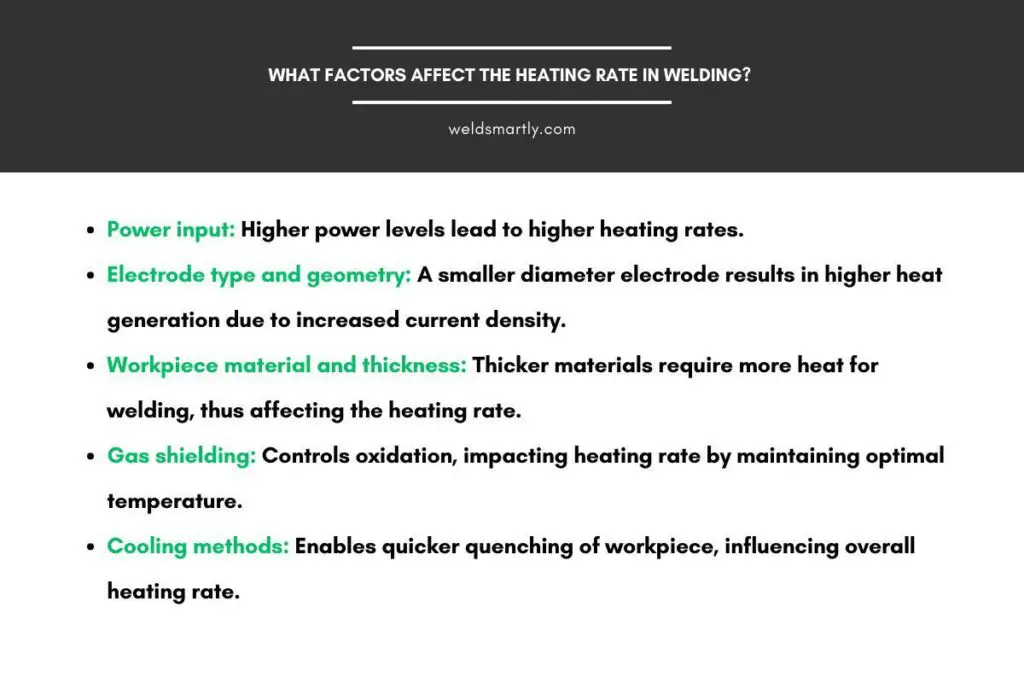

What factors affect the heating rate in welding?

The heating rate is affected by several factors, including power input, electrode type and geometry, workpiece material and thickness, gas shielding, and cooling methods.

In general, higher power levels result in higher heating rates. Electrode type and geometry also play a role in increasing heating rate – for example, a smaller diameter electrode will result in higher heat generation due to its higher current density.

Workpiece material and thickness also affect heating rate because more heat is required to weld thicker metal.

Finally, gas shielding and cooling methods can help control the heating rate during welding by controlling oxidation and enabling faster quenching of the workpiece. Overall, understanding these factors can help optimize heating rates for specific applications.

Solidification Rate

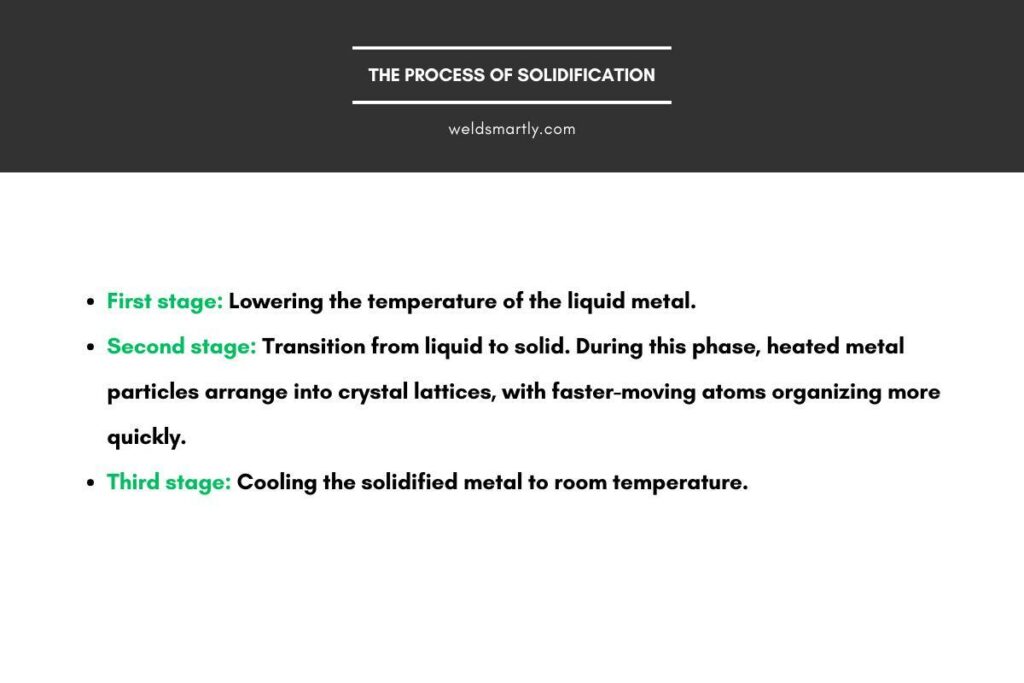

In welding, you can define solidification rate as the time it takes from beginning to end. This means how quickly the weld metal would solidify. The process of solidification occurs in three stages.

First, the temperature of the liquid metal has to go down.

Secondly, it’ll turn from liquid to a solid-state. When metal is heated, moving particles get into a specific order to form crystal lattices. The faster-moving disordered atoms are able to arrange themselves in these ordered structures quicker than slower ones.

Lastly, the newly solid metal has its heat brought down to room temperature.

This is a significant matter in fusion welding processes as this determines the structure and property of a metal. Moreover, the solidification of the metal zone will control the weld-metal microstructure, hot cracking, porosity, weld metal properties & gran structure.

FAQs

Is a higher cooling rate good for welding?

Keep in mind that the higher the cooling rate, the less time it is for heat to diffuse through the weld metal and heat-affected zone (HAZ), and the more likely it is that microstructural defects will form. These defects can reduce the strength and toughness of the welded joint. Therefore, a high cooling rate should be avoided if possible.

What is the relation between cooling rate and solidification rate?

When welding, the cooling rate determines the solidification rate. A higher cooling rate is a decrease in the solidification rate. While the opposite is that a lower cooling rate during welding will lead to an increase in the solidification rate.

Final Words

Have you ever struggled with a welding project? Maybe knowing about the cooling rate, heating rate and solidification rate would have helped you achieve better results.

It is always important to remember that the cooling rate, the heating rate, as well as the solidification rate play a role in the final outcome of welding. By understanding these concepts, you can weld metals together more efficiently and create products that are stronger and last longer.

Let us know in the comments how you plan to use this information in your future welding projects!