As a company, Hobart Welders needs no introduction. The success of this brand is as much associated with its large variety of welding and cutting equipment as the durability and performance of its appliances. Hobart Handler 140 is one of the top MIG welders with hundreds of positive ratings.

Why should anyone bother about this one where there are several other welders with nearly the same reputation? In this review, I’ll try to answer this very question and reveal everything the truth about it.

My In-Depth Hobart Handler 140 Review

First up, I’ll let you know what you’ll see as you unbox the product. Then, I’ll explain its build quality, usability, safety, performance, and other factors in detail. You have quite a few things to know, don’t you? Let’s get to it.

A Look Inside the Package

The Handler 140 package includes all the essential components and standard accessories. You can hold the HR-100 gun comfortably by the hand, and its work cable reaches up to 10 feet or 3 meters. Oh, a work clamp, thickness gauge, power cord, and plug are also included.

Without much practical experience, you might feel a little uncomfortable. The owner’s manual and maintenance guide makes it easy as it shows you how to install, operate, and troubleshoot the unit.

Some of the built-in components include a solenoid valve, a dual-gauge gas regulator, and a hose. The spool hub accommodates spool sizes in two categories, such as 4 and 8 inches. You’ll get a .spool of 030-inch flux-cored wire and contact tips for the same size. These are free samples. A drive roll is also available in the package.

Build, Ease Of Use, And Safety

The 57-lb machine doesn’t cause much of a problem as you want to move across your workplace or job site frequently. Its wire drive uses industrial-grade heavy-duty cast aluminum, which facilitates the speed at which the wire feeds.

The control panel features a sloped design that increases the visibility of the unit’s user interface for operators to adjust the settings and see each part of the interface.

Voltage plays a crucial role in shaping the characteristics of the arc created in the welding process. Wouldn’t it be nice to have five different voltage ranges instead of a fixed number? The Handler 140 offers five different positions so that you can set the voltage as your job requires.

The drive roll, labeled as the ‘Quick Select,’ has three grooves, two for .6/.8/.9 mm or .024/.030/.035 inch of solid wire and one for .8/.9 mm or .030/.035 inch of flux-cored wire.

Maybe, you know, but I should mention that you need to change the polarity as you switch between the flux-cored and solid wire. The polarity changeover switch makes it convenient for you.

The spool hub is built to accept both large and small spools (4 or 8 inches), which lets you enjoy the flexibility to choose wire as your welding project requires.

Resetting or changing the unit’s circuit breaker would be a massive challenge if the thermal overload and motor protection systems were not in place. Both mechanisms rely on a self-resetting function to protect the power transformer and the motor from damages in any case of overload.

Power And Performance

Being able to ensure that the arc is stable and smooth is critical. Open-Circuit Voltage (OCV) is an essential aspect of how the arc should be. In this case, it is 28 VDC. You may love to look at 50 or a higher number. Come on, my friend! Be realistic. It is not easy to find a machine with a higher OCV at the price of this welder.

I cannot call this Hobart machine the best of all MIG welders as far as arc performance is concerned. Still, this unit outperforms many of its cheaper competitors and even some of the costlier alternatives.

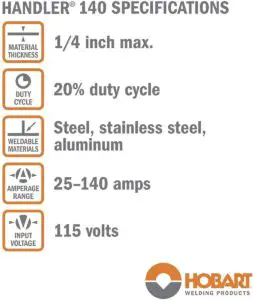

The amperage falls between 25A and 140A, where you’ll get no less than 90 A at 18.5 DC as the rated output. I would say it is NOT bad for a 115 V MIG welder.

Let’s look at another number – the duty cycle. I know there are welders with higher duty cycles than 20%. But you won’t complain if you’re tackling a DIY or light-duty project.

You can operate this unit for as long as two minutes without a pause out of a standard operational cycle of 10 minutes. You want to maintain this to avoid any instances of the unit getting overheated.

The wire feed system works at a speed of 40 to 700 inches per minute (ipm). You can get it slightly faster at zero loads, I mean 50–740 ipm.

Material Thickness

As you try to know what thickness this welder can handle, the first thing you’ll learn is what its label says, 24 ga. to 1/4 inch. Also, the best choice of metal for this machine is mild Steel.

If you can settle for less than the highest quality, you have more options to try. In practice, you must consider the diameter and type of the wire, the shielding gas, and the base metal in use.

So, you should know how to combine these elements following the ‘welding guide.’ The following chart will help you with the right combinations.

| Base Metal | Shielding Gas | Wire Type | Wire Diameter | Material Thickness |

|---|---|---|---|---|

| Steel | Argon and CO2 | Solid | .024, .030, and .035 Inch | 24 Gauge to 1/4 Inch |

| Steel | CO2 | Solid | .024, .030, and .035 Inch | 24 Gauge to 1/4 Inch |

| Steel | No External Gases | Flux-Core | .030 and .035 Inch | 18 Gauge to 1/4 Inch |

| Stainless Steel | He + Ar + CO2 and Ar + CO2 | Steel | .024 and .030 Inch | 18 Gauge to 10 Gauge |

| Aluminum | Argon | Aluminum | .030 Inch | 16 and 12 Gauge |

Applications

Both DIY and professionals go about choosing a welder in two ways. Choose your unit with one specific application in mind or get one that serves you regardless of the applications. The question is how you should approach it.

According to the manufacturer, the unit can be picked up by those handling home and farm projects or working at an auto repair and restoration workshop. Based on my findings, the claim is well-founded, except that the quality of the weld may not be as high as you need in all of these areas.

Frequently Asked Questions

Before passing my final remarks on Hobart 500559, I think you could gather and use the following information. These are questions Hobart’s customers often ask. I’ve tried to explain a few things about the product in layman’s language.

Can I Weld 1/4-inch Square Tubing With This Machine?

Answer: Yes, you can weld this specific tubing. Make sure its wall is thinner than 1/4 inch, for which the tubing needs to be 1/4 inch. Pick up .024-inch solid wire and use a mix of shielding gases (75% Ar + 25% CO2).

Avoid using flux-core wire because welding without external gases will only add heat to the material, causing a burn-through issue. Also, dovetail the ends of your material if two pieces are welded together.

Can I Use The Flux-core Method To Handle 18-gauge Steel?

Answer: With the correct amperage and WFS settings, you may not risk burning through 18-gauge Steel. Choose .030 or .035 wire, keeping in mind that the smaller diameter works better. You must adjust the heat and WFS to avoid overheating and burn-through.

I’m offering you two basic rules that should help you calculate the required amps and WFS. With adequate experience, you may adjust settings without adhering to these rules strictly.

- You need 1 amp of power for .001 inch of metal thickness.

- Multiply per amp by 2 inches for .030-inch wire to find the WFS (expressed in IPM or inches per minute).

What Size Gas Tank Should I Buy?

Answer: Since you have to use a cylinder cart and Hobart provides a good one, you should stick to its dimensions, especially the diameter (7 inches) and weight capacity (up to 75 lbs.). Choose a tank with the following specifications.

- Capacity: 83cf

- Height: 32 Inches

- Diameter: 7 Inches

- Weight: 47 lbs.

You may see small variations in the numbers, but the above ones are part of one of the most familiar gas tanks used by welding professionals.

Do I Need Any Special Tools Or Accessories To Weld Aluminum?

Answer: Since the aluminum wire is softer than its steel counterpart, a spool gun that connects to the machine directly can do the trick. Unfortunately, this welder is not designed to accommodate a spool gun that connects directly.

However, you can weld 16 and 12 gauge material using pure argon, 4043 AL, and 5356 AL wire with the polarity set to DCEP or Direct Current Electrode Positive.

Can You Tell Me The Best Gas Regulator Settings For Argon And CO2?

Answer: For anyone using CO2 and Ar, 20 cfh (cubic feet per hour) is an excellent point to start with. You may change this slightly if you are aware of the outcome.

Shall I Get Any Warranty?

Answer: Hobart offers a ‘5/3/1’ warranty commitment which includes five years on the rectifier, stabilizer, and transformer; three years’ support on the PC board, drive, and generator; and one year of coverage for the MIG gun.

Alternative Product

Check our in-depth comparison between Hobart Handler 140 Vs Lincoln 140. A quick comparison table for your convenience –

Table could not be displayed.Final Verdict

Well, it is time for a conclusion which I know you’ve been waiting for. At this end, you should look at the price, which is as good as a thousand bucks.

It means you don’t want to miss the power and versatility of a decent welder. This Hobart machine stands somewhere in the middle of a high-end unit for home and commercial work and an entry-level product.

I know this statement requires clarification. As long as you keep yourself busy with auto body repair, DIY, or farm projects where you weld thin metal sheets, you’ve got an excellent choice here. If you want to see how it performs on a commercial fabrication project, other Hobart models are worth your consideration.

That is all I found about this welder. Do you have more questions? Feel free to shoot a message.