The right combination of equipment is on any welder’s bucket list. A ground clamp stands first in that combination since it contributes to accomplishing a project flawlessly and prevents leakage, poor welds, and other restrictions.

Companies have been developing newer clamp models with more perfection over time. While that is a good news, it also makes the selection process strenuous. But we got you covered there.

Our part is to introduce the best welding ground clamp to you. Your part is the easiest. Just read each review to learn how it can serve your specific purposes.

Let’s get down to business now, shall we?

11 Best Welding Ground Clamps Reviews

1. Lincoln Electric Grounding Work Clamp

You know how a brand wins your heart over, and when you hear its name, and immediately trust its products? Lincoln Electric is that kind of brand. So you can expect it to deliver fantastic products, and Lincoln will not disappoint you.

The grounding work clam from Lincoln is its star product. It has a construction of nickel-plated steel and replaceable hardware with copper plates.

The clamp has a warranty period extended to an entire year. That is something you will not get with most lamps. The price range is reasonable enough if you look at its quality. There are contact cleats designed very well for your jaws.

It accepts cable sizes from 0 to 2. However, we felt that it needed better support. For example, you could use mechanical wire, hose clamps, or zip ties to attach the cable tightly to the clamp’s handle.

The weight is no more than 1.60 ounces. You can weld electrical ground earth comfortably because the clamp will complete electrical circuits with positive welding arcs.

A point to highlight here is that the clamp is pretty big. That allows you to use it for items hard to ground like large bolts, suspension components, or axle housings.

- A large opening

- Precision in design

- A year of warranty

- Fitting for items difficult to ground

- Replaceable contacts

- Cable support required

- Too big for people with small hands

2. Wal Front Welding Ground Clamp

Durability is what makes this one the best welding ground clamp. It has electroplating with excellent wear resistance. So you can use it for ages. Besides, the high-quality copper gave it good conductivity. So even a beginner can assemble it conveniently.

The clamp makes a suitable replacement for a manual welder. Moreover, you can be confident of its reliability and stability. What’s more, Wal Front lets you choose between the Dutch and US types.

The weight varies from 9.7 to 11.8 ounces and has a current rating of 500A. You will also get fantastic support after purchasing the clamp. For any problems with the clamp, contact the manufacturer to get it instantly solved.

- Exceptionally long-lasting

- Electroplated and resistant to wear

- High-quality, beginner-friendly, and reliable performance

- Great after-sale service

- Dutch and US types are available

- The handles need more improvement.

3. Hobert Welding Ground Clamp

One of the beautiful features that made me look into the product is its sophisticated design. I could not help admitting that the manufacturers made a brave move to another level. But surprisingly enough, they did not do it at the cost of efficiency. Instead, they came up with a better and unique design with zero lackings in ergonomics.

From what I can tell from its construction, it is best on steel, but I am not sure about its performance on aluminum. That should not be any concern if you have only medium to small jobs. You can easily do 1–gauge tasks without facing lots of complications.

The clamp is perfect for those activities where you cannot put clamp-ons without any issues. However, the magnet is not that strong. It will do the job, but I suggest you look for other options if you want a mighty magnet.

- Ergonomic and unique design

- Suitable for steelwork

- Compatible for heavy-duty activities

- Easily manageable

- Usable where clamping is difficult

- The magnet is not much strong.

4. Hitbox G Ground Welding Earth Clamp

Hitbox G has the best welding ground clamp for more accessible and more steady arc strikes. It has also attracted many welders’ eyes by virtue of its solid build and construction quality. The clamp is extraordinarily reliable simultaneously. Once you get your hands on it, I am pretty sure you will not have to go hunting for another clamp for a really long time.

The clamp has no springs to use during your work. The benefit of that is that it will not loosen every once in a while. While I have talked about its reliability, I am yet to mention its convenience. Any beginner will find it straightforward to manage.

The brass construction will help you reduce welding splatters. Now that is a feature every welder wants to enjoy.

There is a three-way attachment mechanism in the clamp. I think that is the most amazing part of it. The attachment allows you to play around with your set-screws in three different methods when using the clamp.

You will get the offer to avail yourself of a year of warranty if you grab this beauty. The company serves 24 hours online. So if you ever find yourself in a situation with the clamp, fetch your phone and contact Hitbox at the earliest.

- It stays tight and fitting even after rough use

- Brass body to handle splatters

- Superior quality of construction and performance

- A three-way attachment system

- A one-year warranty period

- Compatible wires have a limited range.

5. Hobert 400-Amp T-Style Ground Clamp

You will know Hobert has a different welding clamp when you see its T-style design, the perfect thing for welding activities. Hobert has successfully stirred up an incredible resistance balance capable of taking on 400 amps without overheating. Now tell me what less overheating indicates. Yes, fewer hassles. Who would not love that?

Hobert gave it everything to make it the best welding ground clamp. But if I were to point out one thing that Hobert could have done better, it would be the contact area. It will not cover much of the surroundings when you put it at work. However, the spring tension does enough for the clamp grip. So I would not hesitate to comment that the performance is satisfactory.

If the first demand on your list is a high amp, do not think twice about buying the Hobert clamp. Apart from that, the design is unique and handy. Welders have also found its performance dependable and trustworthy.

The weight is 1.3 pounds, while the material is mighty brass. The price maybe a little too much for some, but it will be so worth it for the design it comes in.

- Quality materials and dependable performance

- Capability to deal with 400 amps

- Distinguishable design

- Less overheating to minimize additional hassles

- Easy to use

- The contact area’s lack of sufficient coverage

- Pricier than other typical clamps

6. US Forge Welding Ground Clamp

If you asked me to review the US Forge Welding Ground Clamp in a single word, I would mention its flexibility. But hey, do not mistake thinking that it will bend and twist! Flexibility here refers to its many benefits and comfortability. It immediately became a favorite of welders when US Forge launched it in the market.

The solid build quality comes with a capacity of 300 amps. This US Forge one will serve you right if you want a clamp for heavy use. Heavy users usually have a concern about the spring of clamps. What if it breaks after several months of use? Well, with this brand’s product, you can say goodbye to your worries. Many users have noted that this clamp’s spring is considerably stiffer than that of other clamps.

However, while that indicates the strength level of the grip, it also says that the user has to put more pressure than usual. So, if the user is not sure if they can pull it off, it is better to look for other clamps.

The material of the clamp is bronze. There is a three-month warranty with it. The price, although not as budget-friendly as you would expect it to be, will indeed deem justifiable when you put the clamp through frequent rough use.

- Suitable for rough use

- A capacity of 300 amps

- A stiff grip

- A resilient spring to last longer

- Availability of three months of warranty

- Suitable only for users capable of putting high pressure on the grip

7. Forney Welding Ground Clamp

The ground clamp from Forney is a 300-amp one with an economical and rugged construction, apt for fieldwork and shop maintenance. For conductivity, it has positive connections.

The clamp length is 8 inches, and the jaw opening is 1.75 inches wide. You can use any welding cable up to no. 02 for it. There is a warranty with the product, which you have to claim within three months with purchase documents as proof.

The product is not difficult at all to operate. So even if you are just in the beginning stage, do not worry about it. Plus, the metal-made clamp weighs only half a pound. So you can use it for pipework, angle iron, and steel plate to get the best result.

- Cost-efficient and affordable

- Suitable for any user

- Positive connections

- Stiffness of the spring grip

- A three-month warranty

- No cable braces

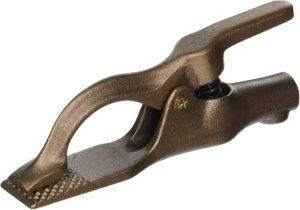

8. KINGQ T-Style Welding Ground Clamp

This piece from KingQ is a bronze one with a capacity of 300 amps. It has a sturdy body built for heavy-duty welding purposes. The jaw opening is 2-inch wide, and it accepts no. 02 cables. It is pretty large for bolt-style attaching lugs.

The clamp has a solid and stiff clamping force. But the contact area is small, which limits its functionality. I think KINGQ should work on the betterment of this.

To talk about the price, it is not bad. I mean, if you have a DIY office, the clamp will do fine. But if you want it to use for professional purposes in a heavy environment, I would suggest otherwise.

You can use the clamp for submerged arc welding, gas metal arc welding, gas tungsten arc welding, and stick welding applications. It is the most appropriate for medium and light duty fabrication of metal.

- Bronze-made with a tight grip

- Notable performance in DIY workshops

- Capable of serving many welding purposes

- Not suitable for heavy-duty professional requirements

9. ESAB Ground Clamp Copper

ESAB has one of the most well-built clamps with a 300-amp capacity. It is quite stout, and it requires grip strength when you open it.

The primary material of the clamp is copper, which ensures high conductivity. That is something you do not usually find in the brass-made once. Of course, it comes at a high cost, but the performance will make you forget that once you start using it.

The clamp weighs only 1.1 pounds, and the installation method is tig-welding. Therefore, it is best suited for stick welding, gas tungsten arc welding, submerged arc welding, etc.

- Lightweight, copper-made, and versatile

- High conductivity

- Amazing performance

- Expensive

10. Tweco Welding Ground Clamp

For anyone looking for an efficient replacement for factory ground clamps, Tweco will be the best welding ground clamp. In addition, it is a multipurpose device for many welders for its multifaceted welding approach.

If you are into submerged arc and stick welding, you can trust the Tweco clamp for its neat performance. In the case of pipe welding, the optimization is for light- and medium-duty fabrications. However, you can carry out gas metal arc welding as well.

The tension in the clamp spring maintains a proper balance. It is neither too soft nor too hard. Along with that, the clamp will also offer you its decent grip. Assuming that you have a medium-range budget ceiling, the clamp will be just the perfect one for you.

- Notable performance

- Balanced spring tension

- A decent grip

- A fair bargain

- Overall satisfactory quality

- The jaw may be malfunctioning sometimes.

11. ANER Welding Ground Clamp

Here is the final product of the best welding ground clamp reviews. It is made of first-rate iron with high durability, hardness, and strength. You can set it up within a second, and it will start to ground instantly. It is suitable for both round and flat workplaces both.

The magnetic power of the clamp is super powerful. It can pull up to 30 KG at once. However, the connection system is simple, and the maintenance is low. You will see an on/off button, which cleans the dust when you switch it on.

Some tips from the company: keep the device off when it has no connection with any ferromagnetic material. You can control it freely to start and stop. A connected ferromagnetic material will generate powerful suction suddenly. Never use a welding ground clamp to carry or transport objects.

- Iron-made and long-lasting

- Powerful magnet

- Simply connection system

- Low maintenance and easy setup

- Affordable price range

- It does not work as well on painted surfaces as it does on clean ones.

How To Select The Best Welding Ground Clamp?

It is not sufficient to know only about the products because their characteristics have to align with your demands. Otherwise, they will not add much value to your work. So here is the buying guide to learn to get the best welding ground clamp for yourself.

The Cable Size

You will need a big cable to bear the current to cover a large ground. When you have to go beyond 200 amps occasionally, your work will require a line no. 2. If it is more than 250, there is no way you can do it with a no. 0.

When you see the products, you will notice that the manufacturing company has mentioned their amp capacity and cable size accordingly. Match both criteria with your work requirements to decide if the product is worth your money.

Pivot And Spring

The best welding ground should be secure enough to cover the ground adequately and maintain your safety while providing the desired performance. For that, it needs to have a stiff spring to have a tight grip.

But that does not mean you should start sweating to squeeze it. If it is excessively stiff, it will damage its pivot before using it much.

Jaw Width And Contact Patch

You do not want a clamp with a narrow contact area. Instead, pick the one with a fine grip and wide contact area. This is a fundamental requirement of every welder from a welding clamp. A clamp will come to no use if it cannot do its job because of its poor jaw width and contact patch.

A tip on the jaw strength: try to find one whose jaw-width is twice your metal work’s thickness.

The Attachment Design

Bronze- or brass-made clamps have the most popular design that uses a setscrew to crush a flat spot with a cable. Other brands use bolts to support the cable size, keeping it between a pair of nuts.

Of these two, the first one is the better-quality method. It will also be helpful if a way supports the cable on a clamp’s body, maybe a tube, tunnel, or loop, so the fragile cover does not give away.

To put it in a nutshell, the cable acceptance of a welding clamp should be convenient. Look into it before finalizing one. If you get a hint that it may become problematic after some time, look for better options.

Frequently Asked Questions

I tried to answer the most common questions about the best welding ground clamp below. See if they help you with additional information.

What do welding ground clamps do?

They connect the enclosure of your equipment to the grounds to ensure their potential is the same. That avoids electrocution that occurs when those make contact. Grounding the sections also limits the voltage.

Why do welders use clamps?

They use clamps because they hold down the metal pieces to keep them safe and secure to weld. They assist you in creating stability in the welding environment to keep the pieces from moving when you work on them.

How many clamp types are there?

Six: AC, parallel, hand, hose, cable, and locking clamps.

Are the clamps negative or positive?

They can be both, depending on the welding type.

Is a brass-made ground clamp good enough?

It is the best. Copper clamps work magic when it is about electrical conductivity. And brass, a copper-alloy, can work with up to 95% efficiency, varying with the structure.

Can one alter their clamp’s physical mechanism?

Yes, considering they have adequate expertise and are willing to do it at the expense of a nulled warranty. However, structural operations are not recommended. It is better if you just buy another more suitable one.

How do I replace a ground clamp?

That is no biggie. Just remove the cable lug securing the cable. Then pull it out from there. Afterward, reverse the steps with a brand-new clamp. That is the general process. It might differ with the types of ground clamps.

How do I use a ground clamp?

First, confirm the connection of the cable with the clamp. There should be no strains in the relief hole. After that, link it up with the workpiece. Clamp it closely to the welding area. See that the connection is perfect, and the clamp has no defects like rust, loose springs, or corrosion.

Where do the clamps go while welding?

It is vital to secure clamps to the materials of the welding bases. In addition, it needs to be within the area’s walking distance. Finally, you can do the clamping straight to the metal plate holding your workpiece. That way, you can avoid affixing it to something leaning against some wall.

Final Verdict

If you have read all the eleven reviews, buying guides, and FAQs, kudos to you! You now know a lot about a welding ground clamp and should find the best one in no time. And I will leave you at it after summarizing my choices.

I have found the clamps from Forney and Aner to be the best within a fixed budget. Forney is also great for home offices and beginners, and so is Lincoln. Hobart is the right one for shipyards and mines with its 400 amps and brass construction.

US Forge and Tweco offer the most efficient clamps for welders with different welding purposes from an all-inclusive sense.

I hope the discussion was informative and helpful for you. Good luck buying the best welding ground clamp!